Detailed explanation of water supply and drainage pipe selection

- Categories:Technical Support

- Author:

- Origin:

- Time of issue:2018-03-27

- Views:130

(Summary description)Glass fiber reinforced plastic sand (RPM) pipe features: 1) Good corrosion resistance. 2) Light weight and high strength. 3) Easy to install. 4) The inner surface is smooth and has high flow capacity. 5) Good low temperature resistance. 6) Good thermal insulation performance.

Detailed explanation of water supply and drainage pipe selection

(Summary description)Glass fiber reinforced plastic sand (RPM) pipe features: 1) Good corrosion resistance. 2) Light weight and high strength. 3) Easy to install. 4) The inner surface is smooth and has high flow capacity. 5) Good low temperature resistance. 6) Good thermal insulation performance.

- Categories:Technical Support

- Author:

- Origin:

- Time of issue:2018-03-27

- Views:130

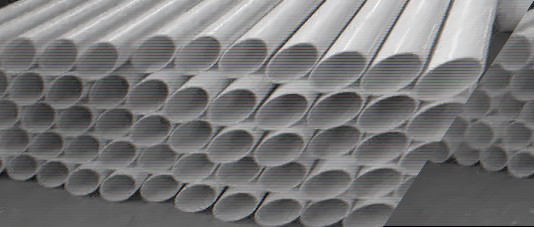

1. Rigid polyvinyl chloride (PVC-U) pipe

PVC-U pipeline structure: It is made of sanitary polyvinyl chloride (PVC) resin as the main raw material, adding an appropriate amount of stabilizers, lubricants, fillers, color enhancers, etc., through plastic extruder extrusion molding and injection molding machine injection molding, The production of pipes and fittings is completed through the processes of cooling, solidification, shaping, inspection and packaging.

Advantages of PVC-U pipes: light weight, corrosion resistance, low water flow resistance, energy saving, quick installation and low cost.

Scope of application: urban tap water delivery and water supply projects, water supply projects inside and outside buildings, water supply projects for industrial and mining enterprises, buried fire protection water supply projects, farmland water conservancy water supply and irrigation projects, landscaping and greening water supply projects, aquaculture water supply and drainage projects, etc.

2. Random copolymer polypropylene (PP-R) water supply pipe

PP-R pipe structure: also known as three-type polypropylene pipe, using random copolymerized polypropylene to be extruded into pipe, injection molding to become pipe fittings. It is a new type of plastic pipe product developed and applied in Europe in the early 1990s. In the late 1980s, PP-R used a gas phase copolymerization process to make about 5% PE randomly and uniformly polymerize (random copolymerization) in the molecular chain of PP to become a new generation of pipeline materials.

Advantages of PPR pipe: moderate price, stable performance, heat and heat preservation, corrosion resistance, smooth inner wall, no scaling, safe and reliable pipeline system, no penetration, service life of up to 50 years. Known as never scaling, never rusting, never leaking, green high-grade water supply material. It has good impact resistance and long-term creep properties.

Disadvantages of PPR pipe: The construction technology requires high requirements, and special tools and professionals are required for construction to ensure the safety of the system.

Application fields of PPR pipes: cold and hot water systems in buildings, including central heating systems; heating systems in buildings, including floor, wall and radiant heating systems; direct drinking pure water supply systems; central (central) air conditioning systems; industrial piping systems for conveying or discharging chemical media.

3. Aluminum-plastic composite water supply pipe

Aluminum-plastic composite pipe structure: The basic composition should be five layers, that is, plastic, hot melt adhesive, aluminum alloy, hot melt adhesive, and plastic from the inside to the outside, the earliest water supply pipe to replace cast iron pipes.

Advantages of aluminum-plastic composite pipe: aluminum-plastic composite pipe has good thermal insulation performance, the inner and outer walls are not easy to corrode, because the inner wall is smooth, the resistance to fluid is small; and because it can be bent at will, it is easy to install and construct.

Aluminum plastic water supply pipes on the market:

1. PE/AL/PE

(Polyethylene/Aluminum/Polyethylene);

2. PE/AL/PEX

(Polyethylene/Aluminum/CrosslinkedPolyethylene);

3. PEX/AL/PEX

(CrosslinkedPolyethylene/Aluminum/CrosslinkedPolyethylene).

The first is that the inner and outer layers are polyethylene, the second is that the inner layer is cross-linked polyethylene, the outer layer is polyethylene, the third is that the inner and outer layers are both cross-linked polyethylene, and the middle layer is aluminum. The first is generally used for cold water piping systems, and the latter two are generally used for hot water pipes.

4. Copper tube

Copper tube structure: also known as copper tube. A type of non-ferrous metal pipe, which is a pressed and drawn seamless pipe.

Advantages of copper pipes: The characteristics of copper pipes are that they have the effect of inhibiting the growth of bacteria on a regular basis. Mechanical strength and damage resistance are also good, but it is not acid-resistant, and is easily oxidized in a humid environment to produce verdigris, which is also a toxic substance. In addition, due to its large thermal conductivity, if it is used to transport hot water, it must be well insulated. Copper pipe has the advantages of high strength, high plasticity, etc. At the same time, it does not contain harmful substances, is pure, natural, has strong rust resistance, does not pollute the environment, has a small coefficient of thermal expansion and contraction, is resistant to high temperature environments, fireproof, and is more resistant to severe cold climates in the north. , suitable for conveying hot water, anti-aging, anti-corrosion, will not be softened by organic matter, will not be penetrated by harmful gases or liquids, is the best water supply pipe.

Disadvantages of copper pipes: high price.

5. Thin-walled stainless steel pipe

Thin-walled stainless steel pipe structure: stainless steel strip or stainless steel plate with wall thickness of 0.6~2.0mm, pipe made by automatic argon arc welding and other fusion welding processes.

Advantages of thin-walled stainless steel pipe: domestic thin-walled stainless steel water pipe is a new type of pipe that came out in the late 1990s. Because of its safety and hygiene, high strength, good corrosion resistance, sturdy and durable, long life, maintenance-free, beautiful and other characteristics, Excellent mechanical properties, excellent wear resistance, good safety and hygiene performance, good temperature resistance, good thermal insulation performance, smooth inner wall and small water resistance; beautiful appearance, clean and fashionable, 100% recyclable; beneficial Water saving; wide range of use; long service life and low comprehensive cost.

Application fields of thin-walled stainless steel pipes: At present, stainless steel water pipes have a strong development momentum and have been widely used in building water supply and direct drinking water pipes.

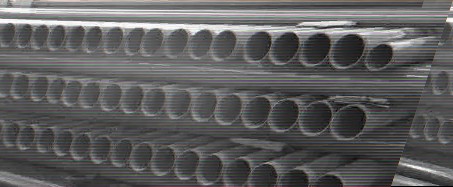

6. Hot dip galvanized steel pipe

Hot-dip galvanized steel pipe structure: Galvanized steel pipe is divided into cold galvanized pipe and hot-dip galvanized pipe, the former has been banned. Hot-dip galvanized pipe is to make the molten metal react with the iron matrix to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after pickling, it is cleaned in the tank of ammonium chloride or zinc chloride aqueous solution or mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to the in the hot dip bath.

Advantages of hot-dip galvanized steel pipe: hot-dip galvanized steel has the advantages of uniform coating, strong adhesion and long service life. The hot-dip galvanized steel pipe substrate undergoes complex physical and chemical reactions with the molten plating solution to form a corrosion-resistant zinc-iron alloy layer with a compact structure. The alloy layer is integrated with the pure zinc layer and the steel tube substrate. Therefore, it has strong corrosion resistance.

Disadvantages of hot-dip galvanized steel pipe: Galvanized pipe is used as a water pipe, and a large amount of rust is produced in the pipe. The outflowing yellow water not only pollutes sanitary ware, but also is mixed with bacteria that grow on the uneven inner wall. . Galvanized pipes have been banned since 2000. At present, galvanized pipes are rarely used in cold water pipes in new residential areas, and galvanized pipes are used in hot water pipes in some residential areas.

Application field of hot-dip galvanized steel pipe: Now the iron pipes used for gas, greenhouse and heating are also galvanized pipes.

7. Welded steel pipe

Welded steel pipe structure: It can be divided into straight seam welded pipe and spiral welded pipe.

Straight seam welded pipe: simple production process, high production efficiency, low cost and rapid development.

Spiral welded pipe: The strength is generally higher than that of straight seam welded pipe. It can produce welded pipes with larger diameters from narrower billets, and can also use billets of the same width to produce welded pipes with different diameters.

However, compared with the same length of straight seam pipe, the length of the weld is increased by 30~100%, and the production speed is lower. Therefore, most of the welded pipes with smaller diameters use straight seam welding, and most of the welded pipes with large diameters use spiral welding.

Advantages of welded steel pipes: high strength and strong strain resistance

Disadvantages of welded steel pipe: poor corrosion resistance, should be treated with anti-corrosion. Steel pipes of the same diameter have different thicknesses, so the wall thickness should be indicated when selecting.

Application field of welded steel pipe: It can be used in fire water supply network.

8. Chlorinated polyvinyl chloride (PVC-C) water supply pipe

Structure of chlorinated polyvinyl chloride (PVC-C) water supply pipe: PVC-C resin is the master batch, and auxiliary materials such as anti-impact agent and stabilizer are added and extruded at high speed.

Chlorinated polyvinyl chloride (PVC-C) water supply pipe features: firmness, easy installation, corrosion resistance, good flame retardancy, not affected by residual chlorine, acid and alkali resistance, bacteria are not easy to multiply, low thermal expansion coefficient and aging resistance Performance, Superior Hygiene Performance Standards:

Application field of chlorinated polyvinyl chloride (PVC-C) water supply pipe: PVC-C pipe is first used in chemical industry, such as chlor-alkali industry, smelting industry, petroleum industry, paper industry, etc.

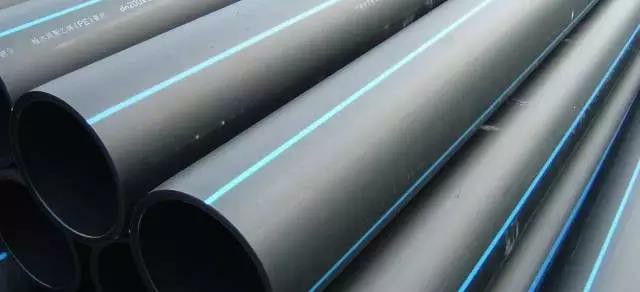

9. Polyethylene (PE) pipe

Polyethylene (PE) pipe structure: polyethylene (PE) resin is the main raw material, and the water supply pipe is extruded.

Polyethylene (PE) pipe features: PE pipe does not add heavy metal salt stabilizer during processing, the material is non-toxic, has no scaling layer, and does not breed bacteria, which well solves the secondary pollution of urban drinking water.

Except for a few strong oxidants, it is resistant to corrosion by various chemical media; no electrochemical corrosion. Under rated temperature and pressure conditions, PE pipes can be safely used for more than 50 years. The PE pipe has good toughness and high impact resistance, and the heavy object directly presses through the pipe without causing the pipe to rupture. The strength of the PE pipe hot-melt or electro-melt joint is higher than that of the pipe body, and the joint will not be broken due to soil movement or live load. The pipeline is light in weight, the welding process is simple, the construction is convenient, and the comprehensive project cost is low.

Polyethylene (PE) pipe application field: used in indoor and outdoor low temperature water supply pipes, etc.\

10. Acrylonitrile-butadiene-styrene (ABS) plastic water supply pipe

Structure of acrylonitrile-butadiene-styrene (ABS) plastic water supply pipe: the material for making the pipe is a mixture of acrylonitrile-butadiene-styrene, of which ABS resin is the main material, and it is only added to improve its physical and mechanical properties. Additives required for performance and processing properties, and the additives should be uniformly dispersed.

Application field of acrylonitrile-butadiene-styrene (ABS) plastic water supply pipe: The chlorinated polyvinyl chloride pipe system used for conveying drinking water shall meet the requirements of GB/T17219-1998.

According to the chemical resistance and sanitation of the material, it is suitable for pressure water supply and drainage, sewage treatment and water treatment, petroleum, chemical industry, power electronics, metallurgy, mining, electroplating, papermaking, food and beverage, air conditioning, medicine and other industrial and construction fields Transport of fluids such as powders, liquids and gases.

11. Plastic coated steel pipe

Plastic-coated steel pipe structure: steel-plastic composite pipe, the product is based on seamless steel pipe and welded steel pipe, and the inner wall is coated with high-adhesion, anti-corrosion, food-grade hygienic polyethylene powder coating or epoxy resin coating. The caliber range DN15--DN1200 can be painted with flanges and pressure grooves. The length of 6m, 9m, 12m and indefinite length coating wall thickness is between 100 microns and 500 microns, usually 350 microns.

Features of plastic coated steel pipe:

1. Hygienic, non-toxic, no fouling, no growth of microorganisms, and ensure fluid quality

2. Chemical resistance, soil and marine biological corrosion resistance, and cathodic disbonding resistance

3. The installation process is mature, convenient and fast, and it is similar to the connection of ordinary galvanized pipes

4. Good weather resistance, suitable for harsh environments such as deserts and saline alkalis

5. The pipe wall is smooth, the conveying efficiency is improved, and the service life is long.

Common steel-plastic composite pipes are: steel-lined polypropylene composite pipe (GSF.PP), steel-lined polyvinyl chloride composite pipe (GSF.PVC), steel-lined polyethylene composite pipe (GSF.PE), steel-lined PTFE composite pipe Vinyl composite pipe (GSF.F4).

Application field of plastic-coated steel pipe: various forms of circulating water system (civil circulating water, industrial circulating water), excellent performance, anti-corrosion life of up to 50 years. Fire water system. Water supply and drainage transportation of various buildings (especially suitable for cold and hot water systems in hotels, hotels, and high-end residential areas). Various chemical fluid transportation (acid, alkali, salt corrosion resistance). Buried pipes and passage pipes for wires and cables. Ventilation pipes, supply and drainage pipes of mines and mines.

12. Plastic-lined steel pipe

Plastic-lined steel pipe structure: take galvanized seamless steel pipe and welded steel pipe as the base pipe, after removing the welding rib on the inner wall, lined with food-grade polyethylene (PE) pipe of the same diameter as the galvanized pipe. The thickness of the polyethylene lining meets the requirements of CJ /T136-2007 standard, it is formed after pressure heating for a certain period of time. It is an upgraded product of traditional galvanized pipe.

Types of plastic-lined steel pipes:

Straight seam welded pipe: simple production process, high production efficiency, low cost and rapid development.

Spiral welded pipe: The strength is generally higher than that of straight seam welded pipe. It can produce welded pipes with larger diameters from narrower billets, and can also use billets of the same width to produce welded pipes with different diameters. However, compared with the same length of straight seam pipe, the length of the weld is increased by 30~100%, and the production speed is lower. Therefore, most of the welded pipes with smaller diameters use straight seam welding, and most of the welded pipes with large diameters use spiral welding.

Application field of plastic-lined steel pipe: It is widely used in the water supply system of cold and hot water of various buildings.

13. Cast iron pipe

Cast iron pipe structure: Ductile iron pipe is a kind of cast iron pipe.

Advantages of cast iron pipes: Compared with steel pipes, the price is cheaper, the manufacture is simple, and the corrosion resistance is strong.

Disadvantages of cast iron pipes: brittle and heavy.

Application field of cast iron pipe: used as water supply pipe for buried laying.

14. High-density polyethylene (HDPE) drainage pipe

High-density polyethylene (HDPE) drain construction: HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, and it is translucent to a certain extent in the thin section. In the water supply and drainage pipeline system, plastic pipes have gradually replaced traditional pipes such as cast iron pipes and galvanized steel pipes and become the mainstream pipes.

Features of high-density polyethylene (HDPE) drainage pipe: Compared with traditional pipes, plastic pipes have significant advantages such as light weight, corrosion resistance, low water flow resistance, energy saving, simple and rapid installation, and low cost. favor.

High-density polyethylene (HDPE) drainage pipe application fields: municipal engineering water supply system, building indoor water supply system, outdoor buried water supply system and residential area, factory buried water supply system, old pipeline repair, water treatment engineering pipeline system, garden, Industrial water pipes in irrigation and other fields, etc.

15. Reinforced polypropylene (FRPP) molded pipe

Reinforced polypropylene (FRPP) molded pipe construction: Glass fiber reinforced polypropylene (FRPP) pipes are produced from glass fiber modified polypropylene raw materials treated with coupling agents.

Reinforced polypropylene (FRPP) molded pipe features: the product has the characteristics of corrosion resistance, high strength, anti-leakage, low internal resistance, tensile resistance, bending resistance, low cost, long life, convenient installation and maintenance, etc.

Reinforced polypropylene (FRPP) molded pipe application fields: widely used in petroleum, chemical, electric power, textile, metallurgy, pharmaceutical, paper, food, mining, garbage disposal, construction and other industries, used as corrosive liquid transportation and process pipelines, deep Trusted by users.

16. Glass fiber reinforced plastic sand (RPM) pipe

Glass fiber reinforced plastic sand (RPM) pipe structure: high-strength glass fiber reinforced plastic as the inner and outer reinforcement layers, and cheap quartz sand/resin as the core layer in the middle to improve the rigidity of the pipe, supplemented by a tough acid-alkali corrosion-resistant inner layer. The lining layer and the outer protective layer meeting the requirements of the working environment constitute the composite pipe wall structure.

RPM pipe can be produced by centrifugal casting or winding process. Therefore, there are two types of composite tube wound tube composite tube and centrifugal cast tube. When the centrifugal casting process is used, the glass fibers are chopped fibers; when the winding process is used, the glass fibers are long fibers.

The maximum diameter of centrifugally cast RPM pipe is 2400mm, and the maximum diameter of filament wound RPM pipe can reach 4000mm. For thermosetting plastic tubing.

Glass fiber reinforced plastic sand (RPM) pipe features: 1) Good corrosion resistance. 2) Light weight and high strength. 3) Easy to install. 4) The inner surface is smooth and has high flow capacity. 5) Good low temperature resistance. 6) Good thermal insulation performance.

Scan the QR code to read on your phone

15195957745

15195957745

Message

Message