China's MBR technology solution leader | ruijiete

- Categories:News

- Author:

- Origin:

- Time of issue:2021-02-01

- Views:0

(Summary description)Nanjing ruijiete Membrane Separation Technology Co., Ltd., established in 2010, focuses on the research and manufacturing of core modules of membrane bioreactor (MBR). It is an environmental protection technology company that actively practices and promotes the development of "environmental protection + Internet" mode in the industry. Its business includes "ruijiete MBR membrane products" and "environmental protection hydrosphere".

China's MBR technology solution leader | ruijiete

(Summary description)Nanjing ruijiete Membrane Separation Technology Co., Ltd., established in 2010, focuses on the research and manufacturing of core modules of membrane bioreactor (MBR). It is an environmental protection technology company that actively practices and promotes the development of "environmental protection + Internet" mode in the industry. Its business includes "ruijiete MBR membrane products" and "environmental protection hydrosphere".

- Categories:News

- Author:

- Origin:

- Time of issue:2021-02-01

- Views:0

Nanjing ruijiete Membrane Separation Technology Co., Ltd., established in 2010, focuses on the research and manufacturing of core modules of membrane bioreactor (MBR). It is an environmental protection technology company that actively practices and promotes the development of "environmental protection + Internet" mode in the industry. Its business includes "ruijiete MBR membrane products" and "environmental protection hydrosphere".

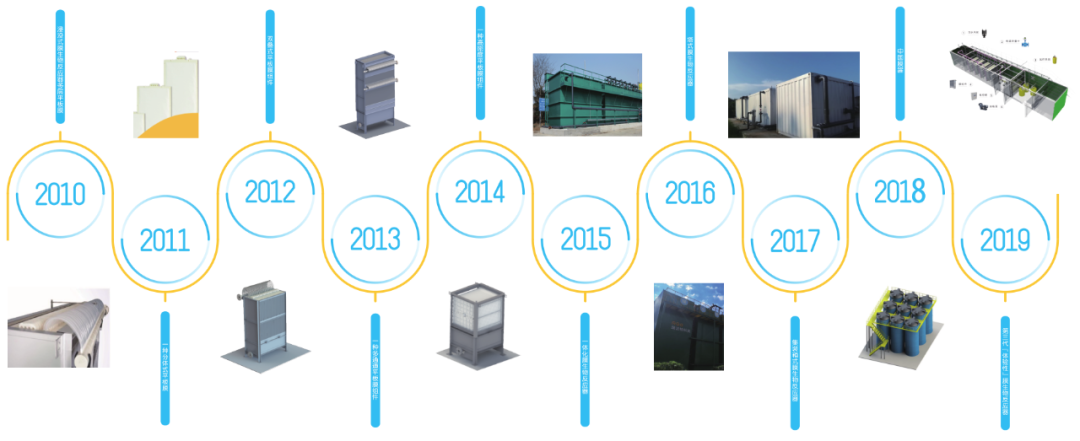

Ruijiete MBR membrane products are used to provide scientific membrane water treatment solutions for environmental protection engineering companies. In 2010, we innovated and developed the double stacked flat membrane and applied for a patent. In 2018, we put into development the MBR membrane tank, and proposed the transformation of integrated and integrated environmental protection equipment to standardization for the first time in the industry.

Environmental protection water circle is committed to building an Internet Ecosystem of environmental protection industry with sharing economy based on we media and community. It is a social and service platform for China's environmental protection industry vertical new media and environmental protection industry chain. It pays attention to more than 300000 environmental protection people. It obtained Cybertron capital investment in 2017.

The company has passed the quality management system certification and the performance evaluation of intellectual property standard implementation enterprises in Jiangsu Province. Successively obtained:

"Jiangsu high tech enterprise"

"Top 100 most growing high-tech enterprises in Jiangsu Province in 2017"

"Excellent enterprises in the 5th China Innovation and entrepreneurship competition"

"2018 Nanjing gazelle enterprise"

"Nanjing Engineering Technology Center"

Ruijiete is a technology driven enterprise.

It has 30 national certified patents, including 2 invention patents, 25 utility model patents, 3 appearance patents and 11 accepted (6 invention patents); There are 5 provincial high-tech products, 6 municipal key promotion new products, and the "third prize" of the scientific and technological progress award of the provincial environmental protection department.

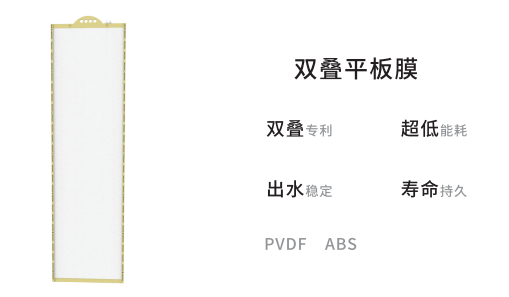

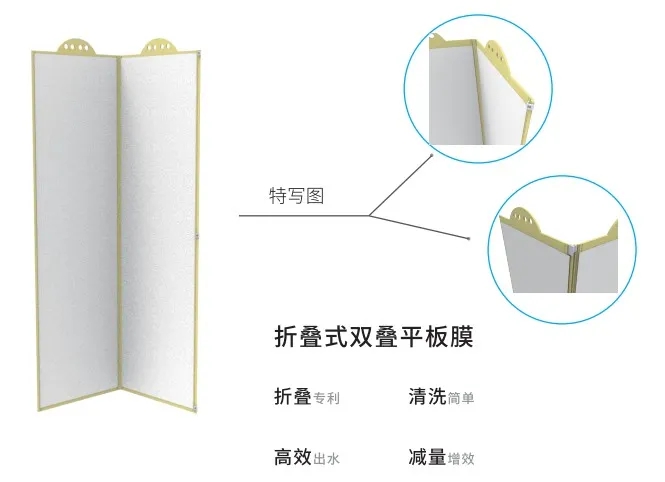

The double stacked flat membrane developed in 2010 is at the leading level in the industry; In the following years, products such as high-density flat film, multi-channel flat film and double-layer double stacked flat film have been successfully developed one after another; The MBR membrane tank put into development in 2018 has guided the transformation of integrated and integrated environmental protection equipment to standardization and modularization.

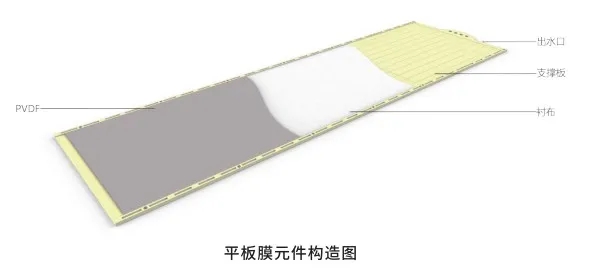

Ultrafiltration flat membrane element is mainly composed of membrane, lining cloth, support plate and water intake. The core material of the element is polyvinylidene fluoride, the material of the support plate is propylene cyanide butadiene styrene copolymer, and the average membrane pore size is 0.1um.

Stable effluent and same process structure design can effectively solve the problem of unstable anti pollution performance; Suitable for the environment without hoisting equipment; Aeration energy consumption decreased by 20%; The yield of sludge in high concentration microbial environment is low.

It is composed of supporting base plate, hinge and buckle. The hinge drives the diaphragm to rotate, which can realize 360 ° free expansion and closure, and effectively solve the problems of film blocking and mud sticking in the process of project application. It is not only convenient for disassembly and assembly, but also improves the later maintenance efficiency and saves the cost.

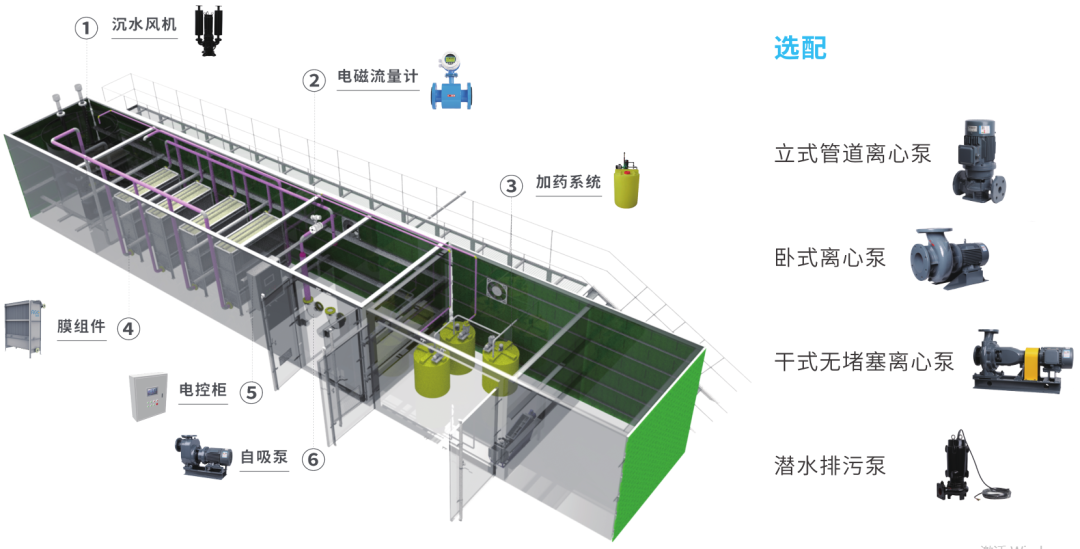

MBR flat membrane module single channel double stack flat membrane module is composed of upper membrane support and lower aeration tank. The membrane support contains a certain number of membrane elements, and each membrane element is connected to the water collecting pipe through transparent silicone hose. The aeration tank contains an aeration pipe for aeration scouring, preventing flat membrane pollution and supplying oxygen to microorganisms.

Membrane bioreactor system

Membrane bioreactor system is a new integrated MBR equipment designed with ultrafiltration membrane as the core technology. It integrates pre filtration, anoxic denitrification, aerobic biochemistry and MBR filtration technology, and the effluent quality is high. Including: Mini membrane tank, double tower membrane tank, skid mounted membrane tank and Chinese tower tank.

(internal structure and common supporting equipment)

Equipment characteristics

Innovation of integration

1. Stripping reflux is adopted, which is characterized by:

① Make full use of the kinetic energy of the water body to form a reflux system through hydraulic stirring;

② There is no need to set dynamic equipment in the anoxic tank, which avoids the trouble of thruster maintenance;

③ The sludge forms vortex in the tank, which is conducive to sludge mixing and ensures sufficient reaction;

④ Compared with the push flow stirring device, stripping reflux can effectively save energy consumption;

2. Coagulation and anoxic integration, which is characterized by the corresponding reduction of process chain and simpler commissioning.

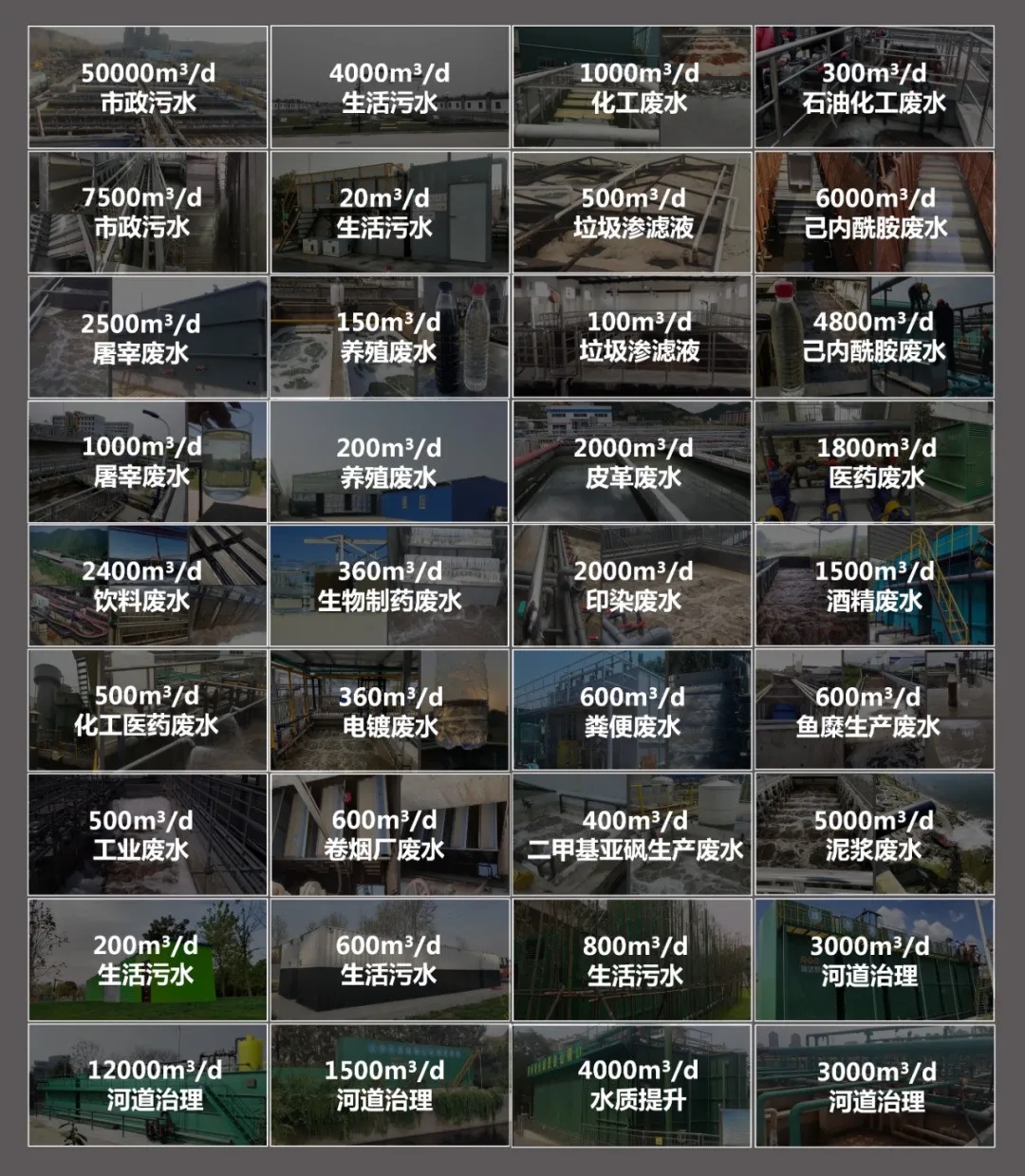

There are more than 1000 successful projects in 30 + regions across the country, covering more than 20 industries, including slaughtering wastewater, aquaculture wastewater, black and smelly river sewage, upgrading and reconstruction of urban sewage treatment plants, high concentration refractory industrial wastewater, landfill leachate and slightly polluted water, of which there are more than 400 in Jiangsu Province.

Scan the QR code to read on your phone

15195957745

15195957745

Message

Message